Fabrication

Specialists in Sheet Metal Fabrication for Roofing and Cladding Systems

Our Capabilities

At CASA, we design and manufacture innovative facade solutions. We offer comprehensive sheet metal and architectural metal fabrication services tailored to the construction industry. From precision-cut panels to custom-formed cladding elements, our advanced technology and skilled craftsmanship ensure high-quality results for projects across Australia.

Cutting & Profiling

Accurate cutting is the foundation of any high-quality metal component. Therefore, we utilize advanced machinery to cut metal sheets with precision, ensuring clean edges and exact dimensions. Whether you need standard profiles or intricate shapes, we deliver consistency and accuracy every time.

Rollforming

Having in-house rollforming capabilities means we can produce high-precision metal profiles efficiently and cost-effectively. This ensures faster turnaround times and greater quality control. Consequently, we deliver seamless, durable, and perfectly profiled components for modern facades, roofing, and cladding applications – all tailored to meet your project’s specific needs.

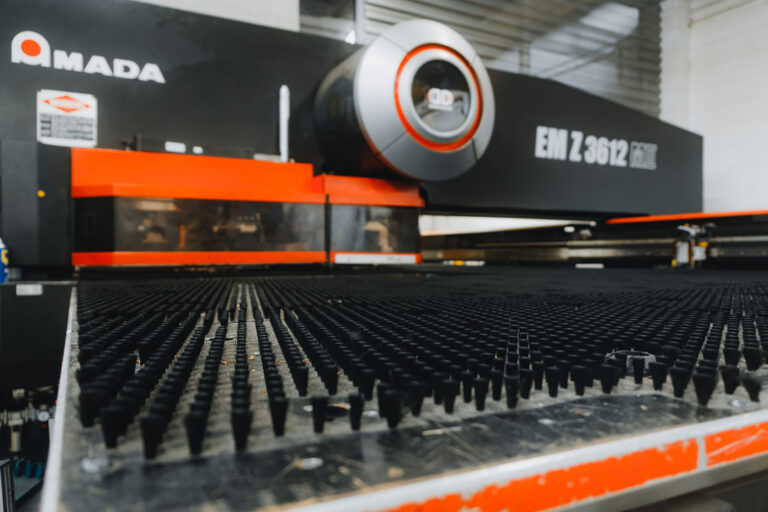

Laser Cutting & Perforation

Using advanced Amada laser cutting technology, we achieve intricate, high-precision cuts with smooth, clean edges. This process is ideal for decorative facade panels, perforated screens, and custom metalwork. Moreover, it offers complete design flexibility while ensuring accuracy and efficiency.

Folding & Bending

Bending and folding metal to exact specifications requires both skill and precision. Our advanced press brake technology enables us to create complex angles, folds, and architectural profiles with exceptional accuracy. As a result, we ensure a seamless fit and finish.

CNC Punching

Our CNC punching capabilities allow for the efficient creation of ventilation holes, fixing points, and custom cutouts in metal panels. This process ensures repeatability and precision. Thus, it is essential for producing functional and aesthetically refined facade solutions.

Welding & Assembly

Strong, precise welds are critical for structural integrity in facade and metalwork applications. Our expert welding team ensures every join is durable, secure, and finished to the highest industry standards. Whether for structural framing, panel reinforcements, or decorative metalwork, we maintain excellence throughout.